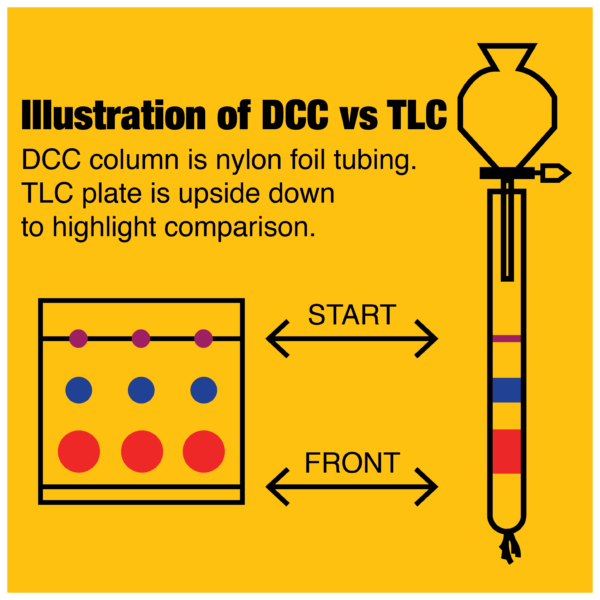

Dry Column Chromatography (DCC)

This technique is useful when you need a fast, easy, and efficient method to purify preparative quantities of substances.

- Reduced solvent requirements

- Highly reduced time of solvent removal of purified substances

- Direct transfer from TLC to column chromatography

- Load significantly higher quantities than prep TLC: multi-gram scale

- Comes with UV-254 indicator – visualize separation progress

- No pumps required; solvent flow is by gravity

- Both silica and alumina adsorbents are available

- Nylon foil tubing is solvent resistant and available in 1 – 6 in. diameters

| Catalog No. | Description | Price (USD) |

|---|---|---|

| 19500-05 | Alumina for DCC, w/UV254, 50-200um, 500g |  Buy now $164.66 Buy now $164.66 |

| 14400-05 | Silica for DCC, w/UV254, 60A, 63-200um, 500g |  Buy now $188.66 Buy now $188.66 |

| 14400-3 | Silica for DCC, w/UV254, 60A, 63-200um, 3kg |  Buy now $660.33 Buy now $660.33 |

| 14400-25 | Silica for DCC, w/UV254, 60A, 63-200um, 25kg |  Buy now $4,402.17 Buy now $4,402.17 |

| NT-1 | Nylon Tubing for DCC, 1in. x 100ft. | |

| NT-1.5 | Nylon Tubing for DCC, 1.5in. x 100ft. | |

| NT-2 | Nylon Tubing for DCC, 2in. x 100ft. | |

| NT-6 | Nylon Tubing for DCC, 6in. x 100ft. |

DCC Experiment

DCC is a “non-elution” method of column chromatography, meaning, the separated substances remain in the column at the end of the chromatographic process. The use of nylon foil tubing allows for the removal of these separated substances by easily cutting the tubing into segments.

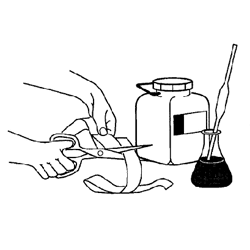

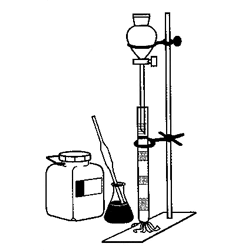

Preparation Of The Column

The nylon foil tubing comes in a roll of various widths in lengths of 100 ft. See table below. Cut the tubing to the desired length. Allow an extra 10 cm for sealing the end. Close one end of the foil by sealing in the flame of a gas lighter, folding and stapling, tying up, or any other suitable method. To remove the folds of the foil, fill one side of the tubing with very hot water, rinse with acetone, and dry with hot air. Insert a pad of cotton or glass wool into the closed end of the tubing and pierce several times with a needle to allow air to escape while the solvent migrates through the column.

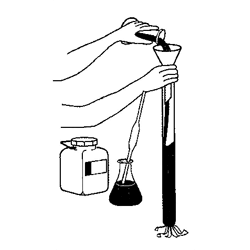

Filling The Column

Carefully fill the tubing, adding small quantities at a time, with Silica DCC, Alumina DCC, or sorbent that has been conditioned with the solvent (mixture). After each small quantity filled, the column should be gently tapped on a hard surface or compacted with a vibrator. Upon filling completion, the column will be so rigid that it will hold itself upright and may be fixed with a simple laboratory clamp to a stand.

Preparation Of The Sample

A few milliliters of a sample solution are added to about 1 g of the sorbent. The solvent is then evaporated using a rotation evaporator until sample and sorbent form a free flowing powder.

A few milliliters of a sample solution are added to about 1 g of the sorbent. The solvent is then evaporated using a rotation evaporator until sample and sorbent form a free flowing powder.

Charging The Column

The adsorbate of the sample is applied as a level layer on the top of the column. This layer is covered with about 2 cm of pure sorbent. If a concentrated sample solution is to be applied, care should be taken to achieve a starting zone, as narrow as possible. Applying liquid sample causes more uneven zones than applying the sample as an adsorbate. After penetration of the solution into the top of the column filling, about 2 cm of pure sorbent will be applied.

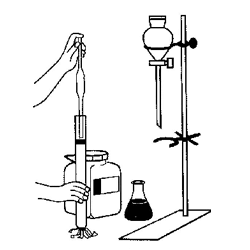

Development Of The Column

The solvent (mixture) that formed the best results in the preliminary TLC experiments is carefully added to the top of the column by means of a separatory funnel. The solvent should migrate slowly and steadily through the column. A constant liquid head of about 1-2 cm gives the best results. A constant liquid head is attained by placing the end of the stem of the topside closed separatory funnel about 1 cm over the top of the column. Depending on the length of the column, the viscosity of the solvent (mixture), and the height of the liquid head, the development of the column should be finished within 15 to 30 minutes. As with TLC, the components of the initial sample mixture should be separated from each other on the column. The solvent volume applied to the top of the column shouldn’t exceed the amount which is necessary to fill the void fraction of the adsorbent bed.

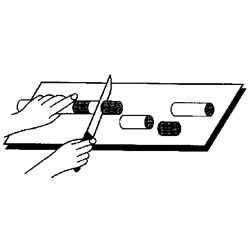

Recovery Of The Separated Compounds

After completing development, the column is immediately placed flat on an appropriate cutting surface. The separated zones are marked on the column, using a UV light if necessary. The column is then cut into sections with a sharp knife. The column may be cut into small slices without sorbent crumbling. The cut slices are placed into Büchner funnels and extracted and processed by appropriate methods.

| Product | pH | Activity | Fluorescent Indicator | Bulk Density (Approx.) | Surface Area (Approx.) |

|---|---|---|---|---|---|

| Silica for DCC | 7 | III | 0.5% | 0.5g/ml | 500-600 m²/g |