Chromabond® SPE Cartridges

Purify, Concentrate, Isolate and Optimize Your Sample

Discover unmatched consistency, purity, and quality with our Chromabond SPE Cartridges. Solid Phase Extraction (SPE) is a fast and efficient sample preparation technique for analyte cleanup, concentration or to isolate your sample from an interfering matrix.

Three Reasons to Use Solid Phase Extraction:

- Concentration of the analyte to increase chromatographic sensitivity and improve limits of detection

- Remove interfering compounds and protect the equipment for subsequent analyses using HPLC, GC, TLC, UV or IR spectroscopy

- Changing an analyte’s environment to an optimized matrix more suitable for downstream analytical analysis

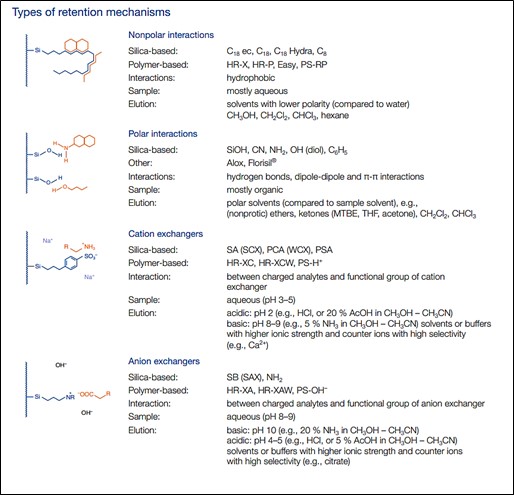

Typical Extraction Mechanisms for SPE

- Reversed phase– extraction of hydrophobic or polar organic analytes from aqueous matrix

- Normal phase– extraction of polar analytes from nonpolar organic solvents

- Ion exchange– extraction of charged analytes from aqueous or nonpolar organic samples

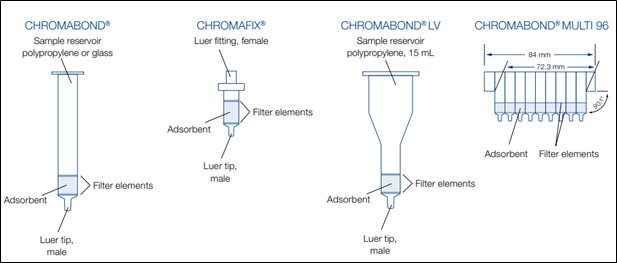

Chromabond SPE Configurations:

All CHROMABOND® columns, cartridges and 96-well plates are manufactured from virgin polypropylene (PP) and non-detectable extractable (plasticizers, stabilizers, etc.) offering quality blank value-free results when using most common solvents.

The high-quality CHROMABOND® adsorbents are kept in place by chemically very inert polyethylene filter elements

(Click on image to enlarge)

Main steps of the SPE procedure

1. Conditioning Of The Adsorbent

Conditioning of the adsorbent is necessary in order to ensure reproducible interaction with the analyte. Conditioning, also called solvation, results in wetting of the adsorbent and thus produces an environment that is suitable for adsorption of the analyte. Nonpolar adsorbents are usually conditioned with 2-3 column volumes of a solvent, which is miscible with water (methanol, THF, -propanol, etc.), followed by the solvent in which the analyte is dissolved (pure matrix, e. g. water, buffer). Polar adsorbents are conditioned with nonpolar solvents. After the conditioning step, the adsorbent bed must not run dry to maintain solvation (deconditioning).

2. Sample Application (adsorption)

The sample application can be performed with a positive or negative pressure with a flow rate of ~3 ml/min. Sample volumes vary from a few milliliters up to liters. Since analytes can be either adsorbed on the SPE packing material or direct flow through while the interfering substances are retained, there are two possible procedures that can be followed. The first procedure is accomplished by following Step 2: Sample Application, then Step 3: Washing and then Step 4: Elution. However, in cases where washing is unnecessary, step three can be omitted such that Step 2: Sample Application is then followed by Step 4: Elution.

3. Washing Of The Adsorbent (optional)

Washing of the adsorbent is usually achieved with a special wash solution; however, in some cases, it may not be necessary. If the polarity difference between the wash solution and the eluent is very large, or if both are not miscible, drying of the adsorbent bed after washing is recommended to improve elution and recovery.

4. Elution

Elution with a suitable eluent should not be too fast. The elution speed depends on the column or cartridge dimensions and the quantity of adsorbent (about 1 ml/min).

| Without Step 3 | With Step 3 |

|---|---|

| Analyte molecules show no interaction with the adsorbent. | Analyte molecules are enriched on the adsorbent. |

| Interfering components and solvent molecules (matrix) are retained. | Interfering components and solvent molecules (matrix) are not retained. |

| Analyte molecules are “washed” from the adsorbent. | Remaining interfering components are washed from the adsorbent. |

| The solid phase is simply used to “filter” the sample. | The analyte is removed from the adsorbent by elution with a suitable solvent |

| 4-Step Method | Reverse Phase | Normal Phase | Ion Exchange |

|---|---|---|---|

| Step 1: Conditioning | Rinse packing Bed with 3-5 mL methanol. 2: Rinse packing bed with 3-5 mL water or buffer. Don't let packing bed dry before adding sample. | Rinse packing bed with 3-5 mL of non-polar solvent. Don't let packing bed dry before adding sample. | Rinse packing bed with 5 mL of de-ionized water or low ionic strenght buffer (e.g. 0.0001M-0.01M). |

| Step 2: Sample Introduction | Apply sample solutions to the top of the packing bed. Push or draw the sample through the bed at a flow rate of 1-5 mL/min. Collect sample for analysis if desired compound has passed through the packing bed with out being retained. | Apply sample solutions to the top of the packing bed. Push or draw the sample through the bed at a flow rate of 1-5 mL/min. Collect sample for analysis if desired compound has passed through the packing bed with out being retained. | Apply sample solutions to the top of the packing bed. Push or draw the sample through the bed at a flow rate of 1-2 mL/min. Collect sample for analysis if desired compound has passed through the packing bed with out being retained. |

| Step 3: Wash | If the desired compound was retained, wash off any weakly retained interfering compound(s) with a polar solvent. | If the desired compound was retained, wash off any weakly retained interfering compound(s) with a non-polar solvent. | If the desired compound was retained, wash off any weakly retained interfering compound(s) with a de-ionized water or low strength buffer. |

| Step 4: Elution | Elute desired compound with 1-2 mL of a non-polar solvent and collect for analysis. | Elute desired compound with 1-2 mL of a polar solvent and collect for analysis. | Elute desired compound with 1-5 mL of a high salt concentration solution (e.g. 0.1-0.5M) or change elution buffer pH such that the sample compound is no longer ionized and collected for analysis. |