NUCLEOSHELL® HPLC Columns

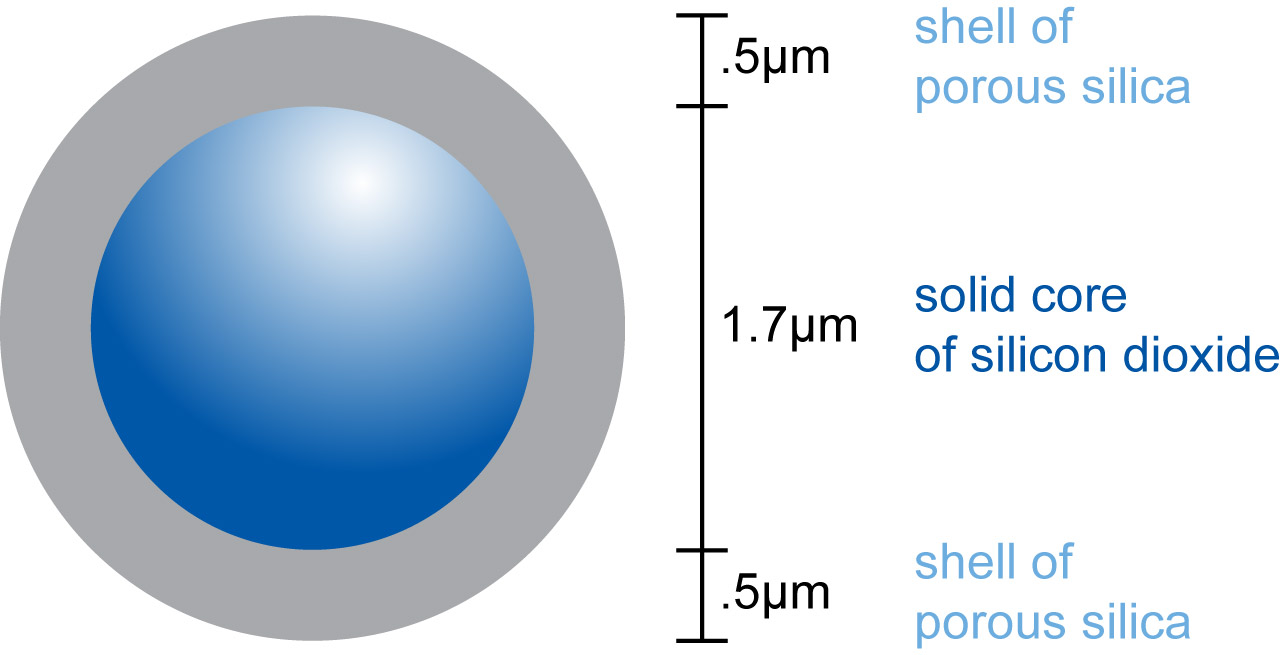

NUCLEOSHELL silica particles consist of a non-porous, solid core of 1.7 µm diameter and a porous outer shell of 0.5 µm thickness. Accordingly, the total diameter of the particle is 2.7 µm.

With conventional fully porous particles, the mass transfer between stationary and mobile phase usually results in peak broadening at higher flow rates (C-term in van Deemter equation).

The short diffusion paths in the core-shell particles reduce the dwell time of the analyte molecules in the stationary phase so that even at high flow velocities of the mobile phase, optimal separation results can be obtained.

The van Deemter plot below demonstrates how efficiency is affected by the flow rate.

In comparison with fully porous silicas, core-shell particles from various manufacturers maintain the efficiency optimum (max. plates/m) over a long range of increasing linear mobile phase velocity.

Core-Shell Technology:

- A solid core of silicon dioxide, a homogeneous shell of porous silica

- Highest efficiency compared to totally porous silica particles

- Particle size 2.7 µm (core 1.7 µm);

- Lower back pressure enables use on conventional LC systems

- Pressure stability up to 600 bar

Benefits of Core-Shell Technology

- Short diffusion pathsRapid mass transfer (C term of the Van Deemeter equation)

- High flow velocity without peak broadening for fast LC

- Narrow particle size distribution (d90/d10~1.1)

- Stable packing

- High heat transfer

- minimized influenced of frictional heat

- column efficiency of NUCLEOSHELL® ~250000/m (HETP ~ 4µm)