Spherical Silica Gel

There are numerous benefits to using spherical silica gel. They are unequalled in the marketplace and far superior to granular silica gels especially for life science/drug discovery industries.

Unique in the Industry. Scale up with ease.

With spherical silica, you now have a direct path for scaling up from analytical to prep to pilot to full-scale manufacturing. This eliminates problems due to inconsistencies resulting from multi-sourced materials.

Spherical silicas are available for all liquid chromatography techniques, with pore diameters ranging from 70Å to 500Å, particle sizes from 2µm to 200µm, and a large selection of bonding chemistries.

One Source. No Variables.

With Sorbtech, your laboratory research has a direct line to manufacturing by way of HPLC to Prep HPLC to Flash Column to Process Column methods, all without any change in the chemistry (the base material or bonding techniques).

For example, a researcher could use a Sorbtech Purity HPLC Column packed with 5µm, C18 spherical silica gel in the laboratory and then move to prep or process scale with 10µm, 15µm, 20-45µm, 40-75µm, or 75-200µm C18 spherical silica gel from the same supply source, thereby eliminating any variables due to a change in chemistry of the adsorbent media.

Advantages of Sorbtech spherical silica gel as compared to granular silica gel

- Wide range of pore sizes to optimize capacity

- Broad selection of particle sizes to optimize efficiency

- Narrow particle size distribution to reduce backpressure

- Lot-to-lot consistency for reproducible results

- Bulk quantities for large-scale applications, no scale-up limitation

- Reserved lots available for process applications

Benefits of Sorbtech Spherical Silicas

- Increase loading – up to 30% more

- Greater reproducibility of process

- Sharper peaks and cost savings (less solvent consumption and labor)

- Longer bed lifetime (decrease cost of labor and silica consumption)

- Better chromatographic results

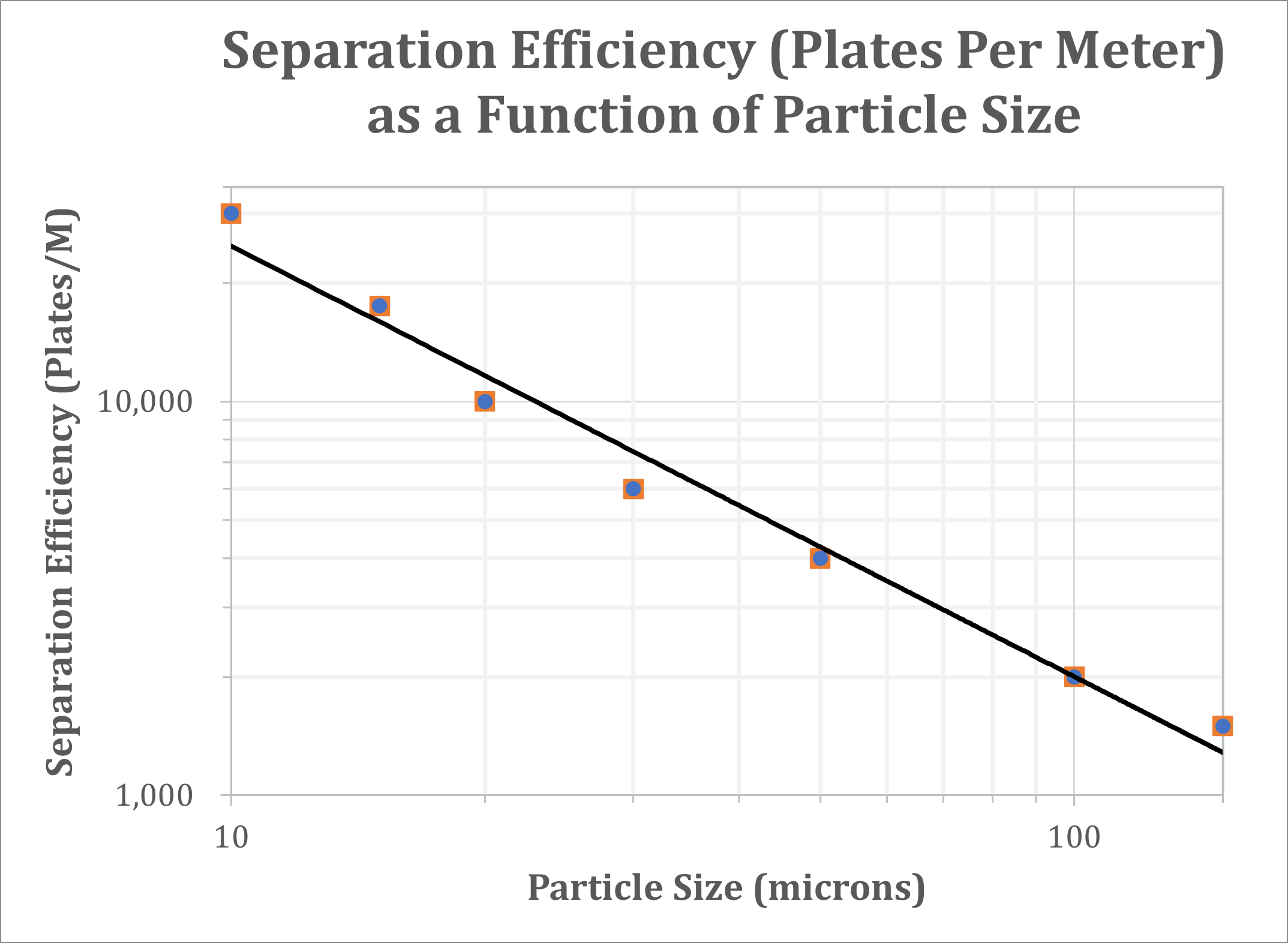

| Particle Size (µm) | Separation Efficiency (Plates/M) |

|---|---|

| 10 | 30,000 |

| 15 | 17,500 |

| 20 | 10,000 |

| 30 | 6,000 |

| 50 | 4,000 |

| 100 | 2,000 |

| 150 | 1,500 |

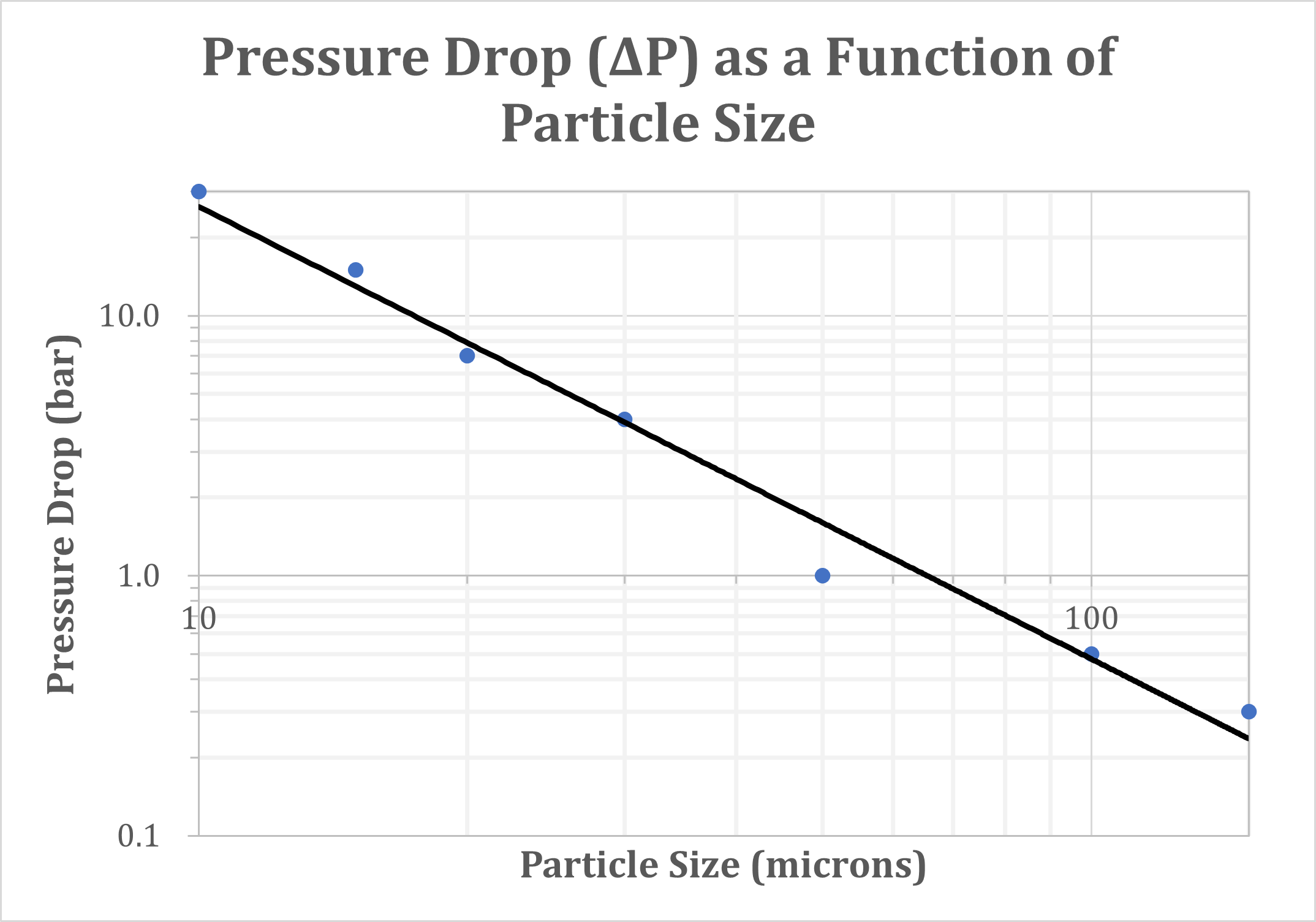

| Particle Size (µm) | Pressure Drop (bar) |

|---|---|

| 10 | 30.0 |

| 15 | 15.0 |

| 20 | 7.0 |

| 30 | 4.0 |

| 50 | 1.0 |

| 100 | 0.5 |

| 150 | 0.3 |