NUCLEODUR®

Fully Synthetical Type B silica (Silica of 3rd generation)

NUCLEODUR offers highly advanced physical properties like totally spherical particle shape, outstanding surface microstructure, high-pressure stability, and low metal content.

NUCLEODUR is the ideal base material for modern HPLC phases.

In RP liquid chromatography the efficiency of the packing is strongly affected by the quality of the base silica itself. Shortcomings in the surface geometry of the particles or metal contaminants are the main reasons for inadequate coverage with the covalently bonded alkylsilanes in the subsequent derivatization steps. It is well known, that poor surface coverage and, in consequence, high activity of residual free silanols often results in peak tailing or adsorption, particularly with basic compounds.

Technical Characteristics

NUCLEODUR® silicas are the successor to the NUCLEOSIL® silicas with a significantly improved silica uniformity. NUCLEODUR® is synthesized in a unique and carefully controlled manufacturing process that provides silica particles, which are totally spherical. The silica is manufactured with a specific pore diameter (110 Å) and particle sizes from 3 µm to 10 µm with very narrow fractionation.

In RP liquid chromatography, the efficiency of the packing is strongly affected by the quality of the base silica itself. Shortcomings in the surface geometry of the particles or metal contaminants are the main reasons for inadequate coverage with the covalently bonded alkylsilanes in the subsequent derivatization steps. It is well known, that poor surface coverage and, in consequence, high activity of residual free silanols often results in peak tailing or adsorption, particularly with basic compounds. NUCLEODUR® Particle Shape and Surface Symmetry “Billiard Balls” in HPLC.

NUCLEODUR® Purity: “Intolerant Towards Metals”

As already mentioned above, highly pure silica is required for achieving symmetric peak shapes and maximum resolution. Inclusions of e.g. iron or alkaline earth metal ions on the silica surface are largely responsible for the unwanted interactions with ionizable analytes, e.g. amines or phenolic compounds. NUCLEODUR® is virtually free of metal impurities and low acidic surface silanols.

Elemental analysis data of NUCLEODUR® 5 µm measured by AAS are listed below.

- Aluminum < 5 ppm

- Iron < 5 ppm

- Sodium < 5 ppm

- Calcium < 10 ppm

- Titanium < 1 ppm

- Zirconium < 1 ppm

- Arsenic < 0.5 ppm

- Mercury < 0.05 ppm

Pressure Stability

The totally spherical and 100% synthetic silica gel exhibits outstanding mechanical stability, even at high pressures up to 800 bar and elevated eluent flow rates. In addition, after several cycles of repeated packing, no significant drop in pressure can be observed. The latter is of prime importance for preparative and process scale applications.

Nucleodur Modifications

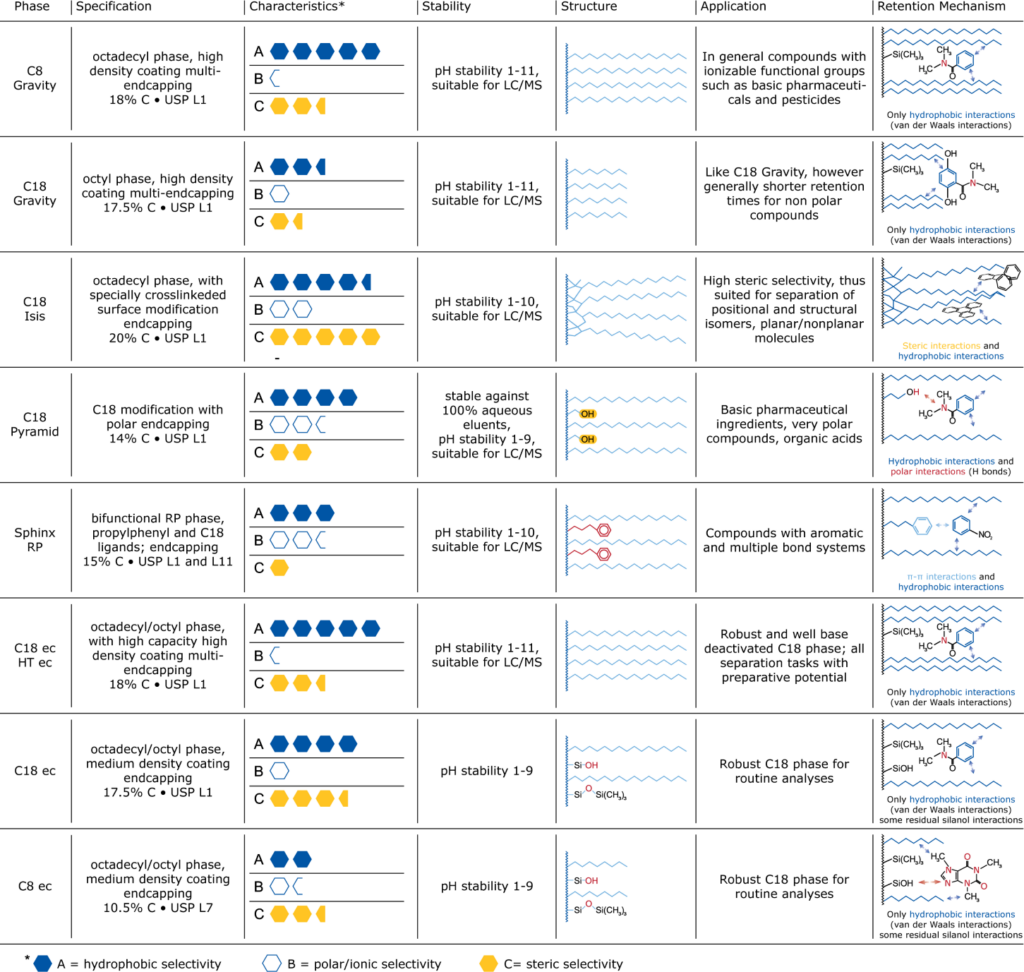

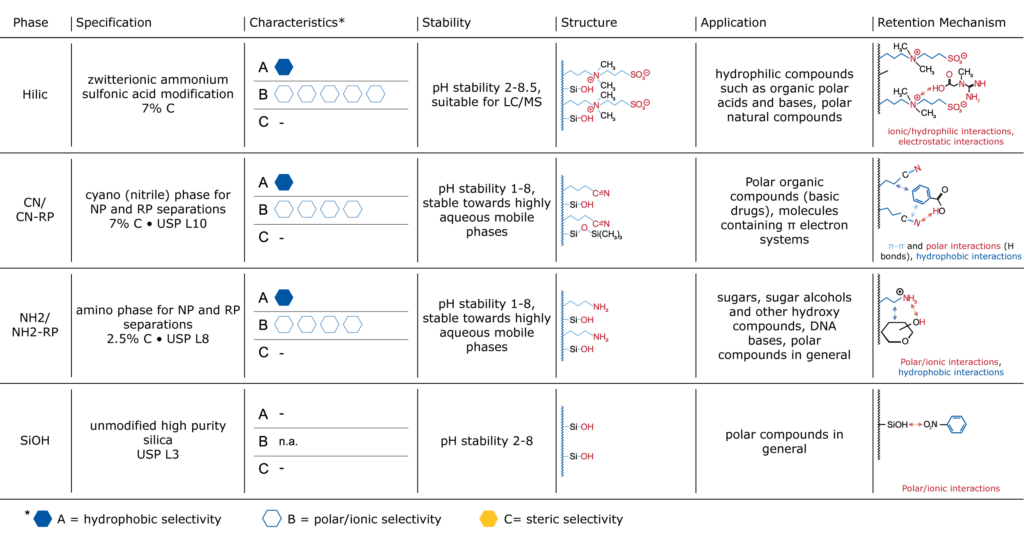

Several different surface modifications based on NUCLEODUR® silica have been developed over the last years providing a full range of specified HPLC phases and an ideal tool for every separation:

- NUCLEODUR® C18 Gravity and C8 Gravity

- NUCLEODUR® C18 Isis

- NUCLEODUR® C18 Pyramid

- NUCLEODUR® Sphinx RP

- NUCLEODUR® CN and CN-RP

- NUCLEODUR® C18 ec and C8 ec

Nucleodur 1.8 µm

- Decrease of analysis time (ultra-fast HPLC)

- Shorter columns with high separation efficiency

- Significant improvement of resolution

- Increased detection sensitivity

- Suitable for LC/MS due to low bleeding characteristics

- All NUCLEODUR® premium phases are available in 1.8 µm: C18 Gravity, C8 Gravity, C18 Isis, C18 Pyramid, Sphinx RP

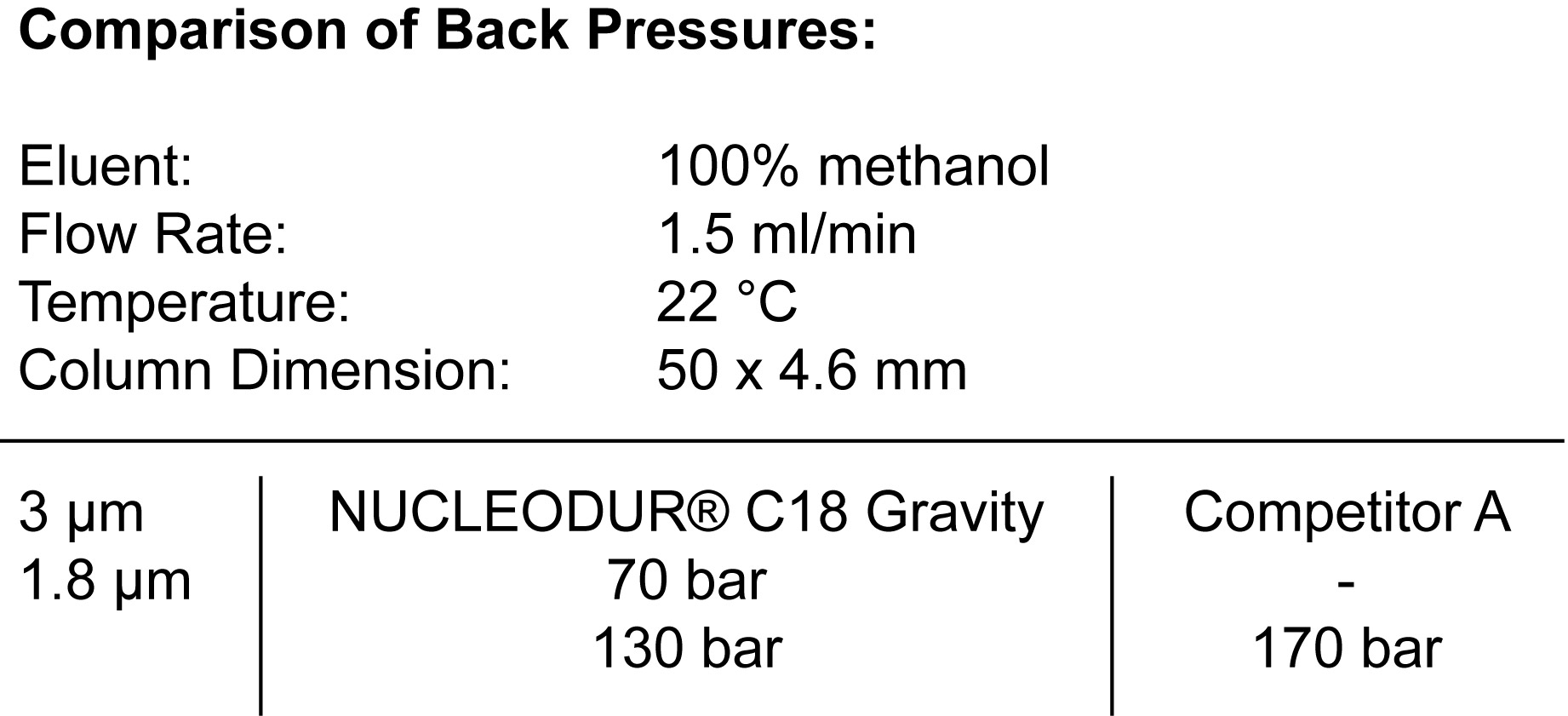

- NUCLEODUR® 1.8 µm particles are fractionated to limit the increase in backpressure

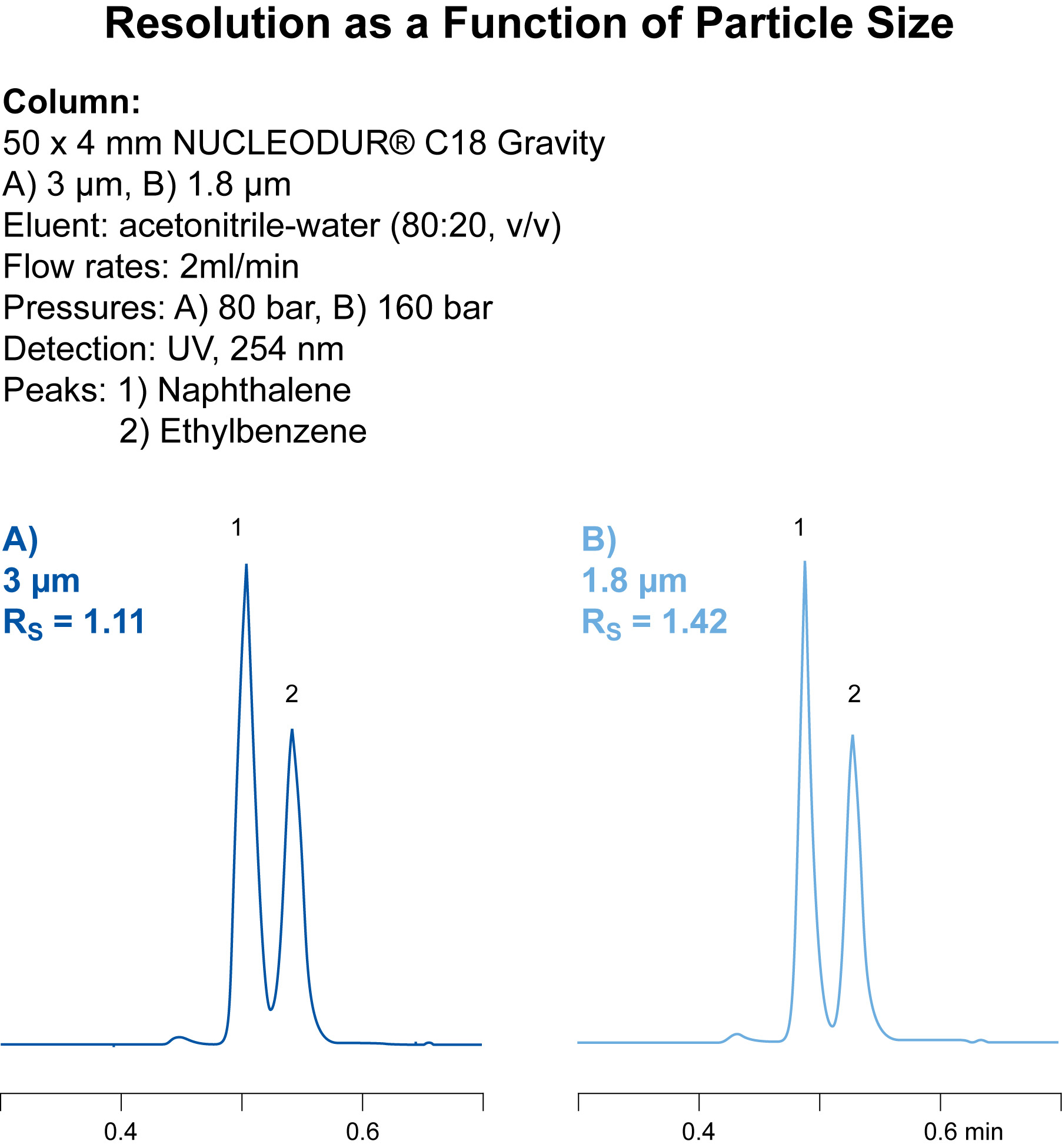

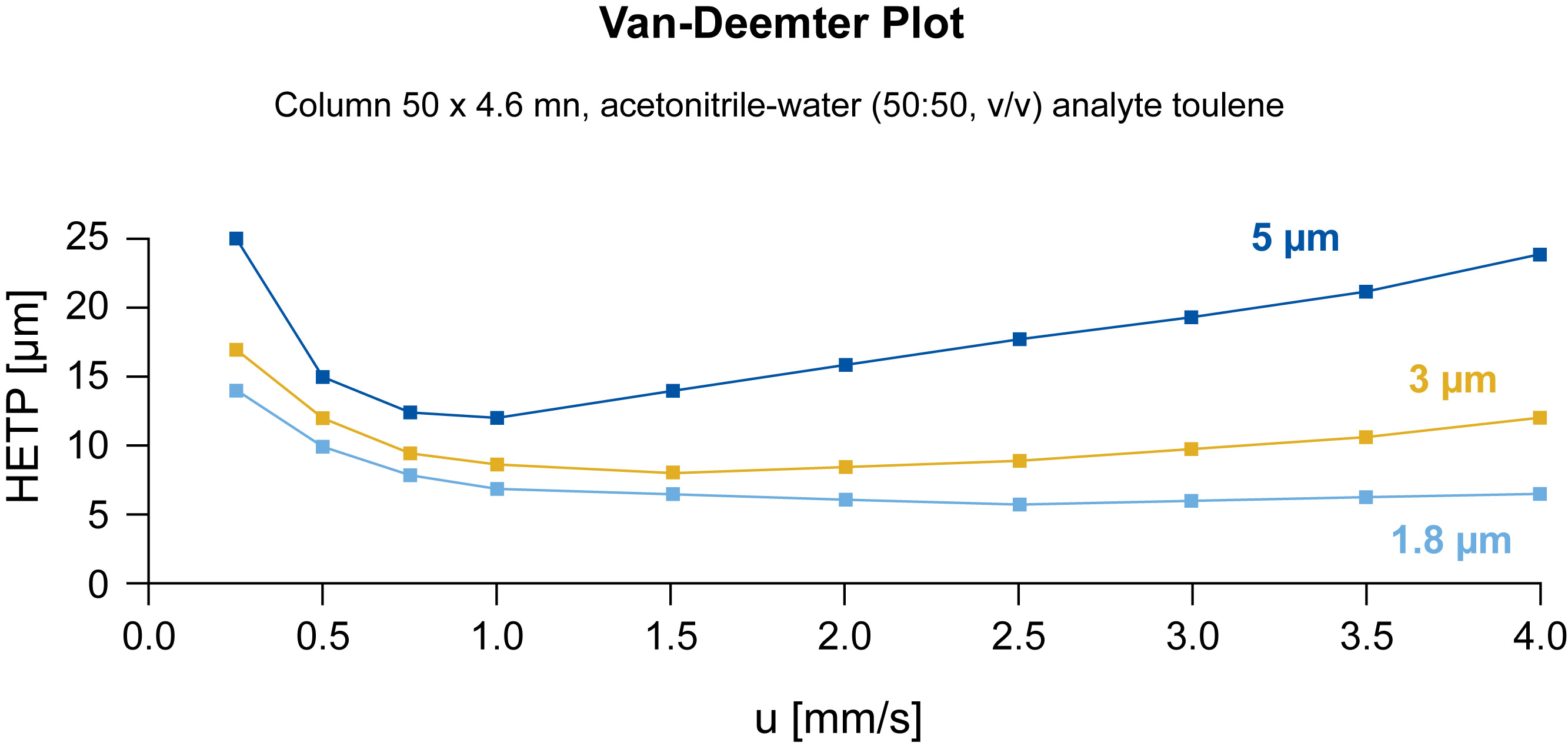

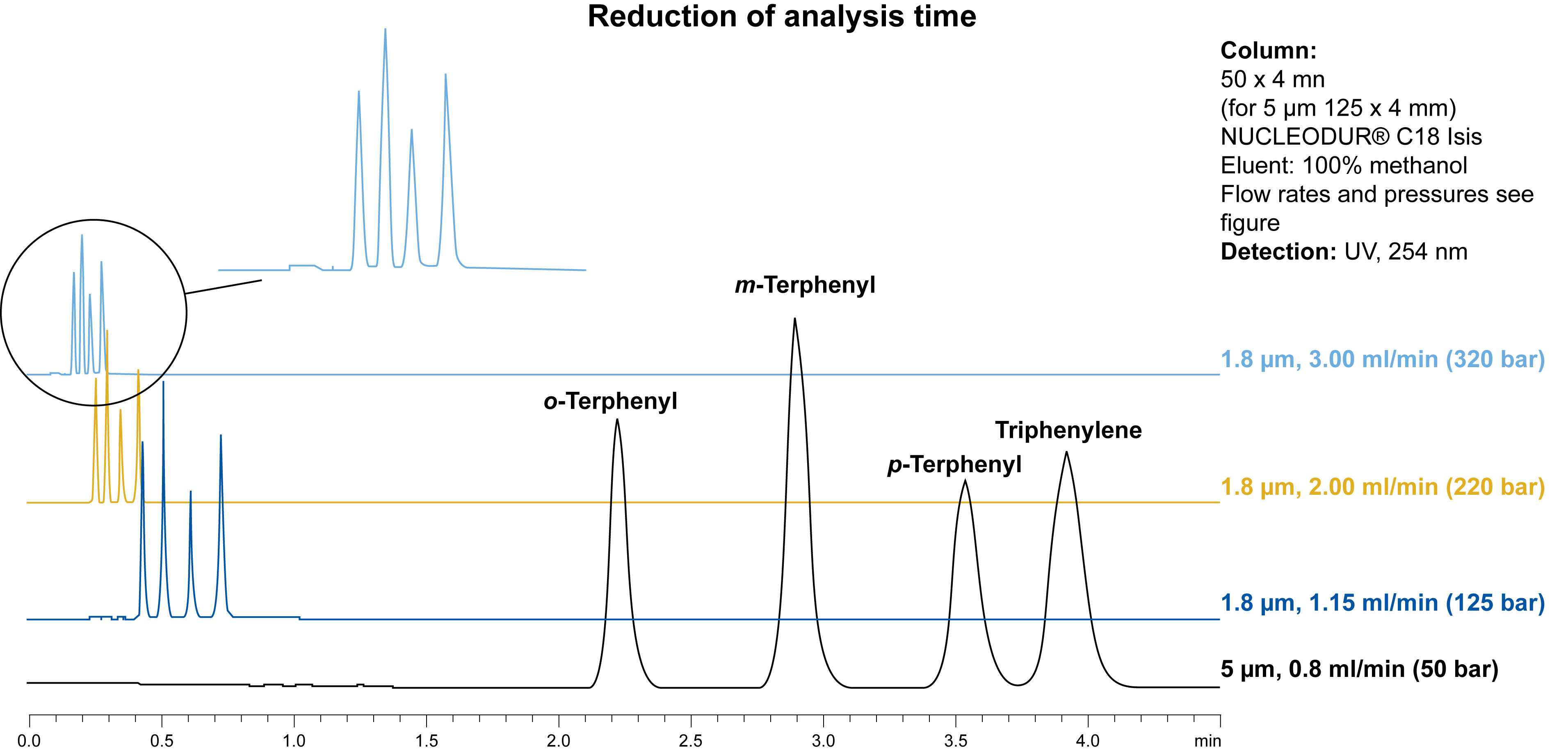

Miniaturization in HPLC has a long history. It started in the early stage of HPLC development with the reduction of particle size from 10 µm via 7 µm to standard 5 µm-which is still the most widely used particle diameter in analytical HPLC-to 3 µm spherical particles which so far was the smallest particle size available for gaining higher theoretical plates and efficiencies. With the introduction of the new 1.8 µm NUCLEODUR® particles now researchers have turned over a new leaf in HPLC column technology. Columns packed with these sub-2 micron particles show extraordinary improvements in terms of plate numbers, column efficiencies and resolution compared with their 3 µm counterparts.

Features of 1.8 µm NUCLEODUR® silica particles:

-

- 50 x 4.6 mm NUCLEODUR® C18 Gravity

- 3 µm: N = 100 000 plates/m (h value = 10)

- 1.8 µm: N = 166 667 plates/m (h value = 6)Increase of separation efficiency by a higher number of theoretical plates (N):

- The increase of the plate number by ~ 67 % offers the possibility of using shorter columns with equal plate numbers resulting in a decrease of analysis time.

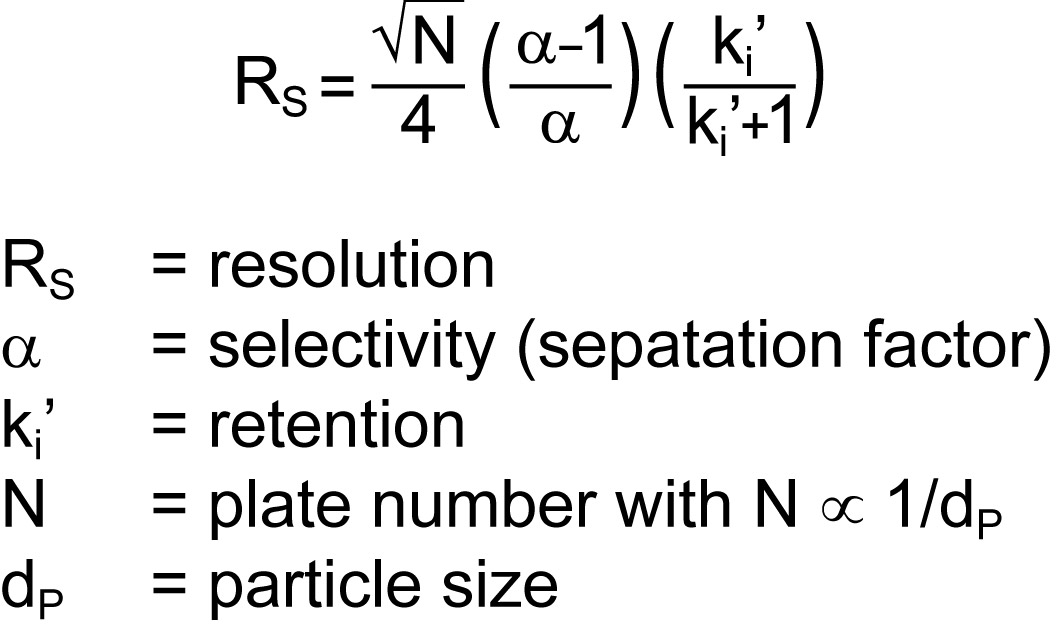

- Significant improvement in resolution

- Use of 1.8 µm instead of 3 µm particles leads to an increase of resolution by a factor 1.29 (29 %) since the resolution is inversely proportional to the square root of the particle size:

- Use of 1.8 µm instead of 3 µm particles leads to an increase of resolution by a factor 1.29 (29 %) since the resolution is inversely proportional to the square root of the particle size:

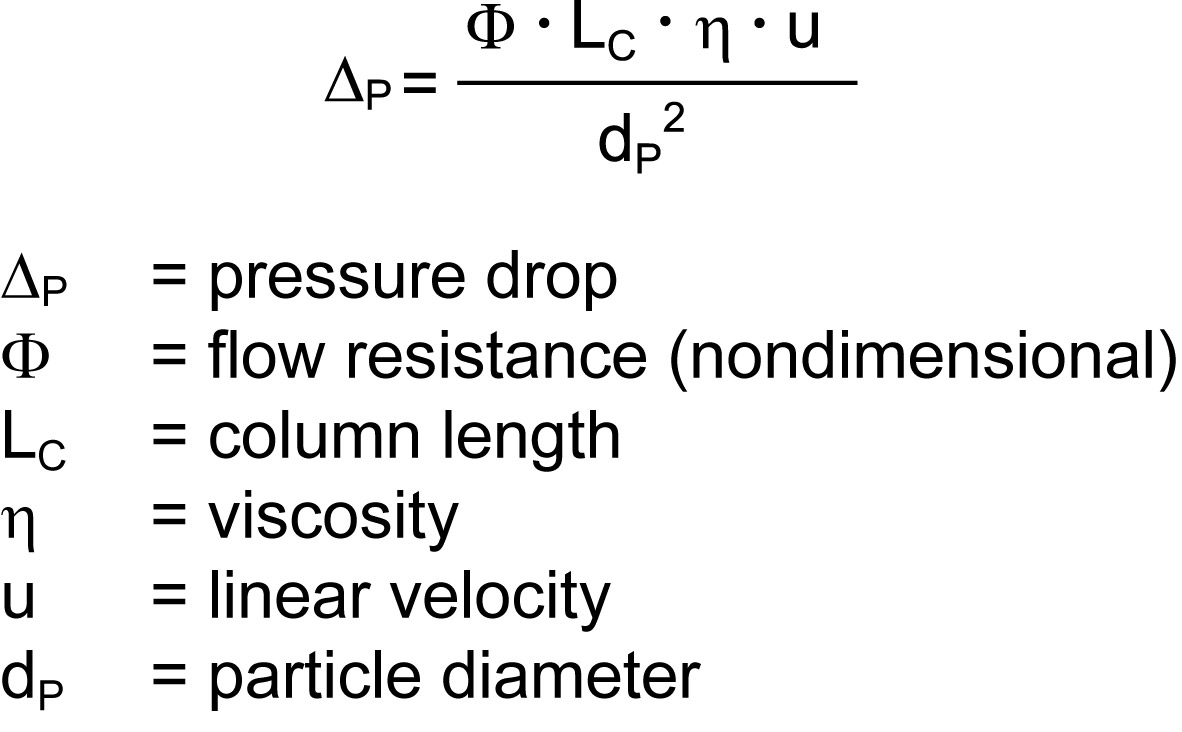

- Column back pressure

- Due to the smaller particle size, the backpressure will increase according to

The high sphericity of the NUCLEODUR® particles and the very narrow particle size distribution keeps the back pressure on a moderate level. Nevertheless, the use of columns packed with sub 2 µm particles generally makes special demands on the HPLC equipment. Pumps should be designed for pressures of 250-1000 bar and the entire system should feature the lowest possible dead volume.

Higher flow rates and shorter run times

Optimal flow rate for 1.8 µm particles is higher than for 3 and 5 µm particles

Technical requirements

To gain the best result in ultra-fast HPLC based on 1.8 µm particles certain technical demands on the instrument are made. Pumps for pressures of 250-1000 bar realizing a flow rate of 2-3 ml are required. The dead volume of the LC system has to be reduced to a minimum. In addition, fast data recording is necessary for an optimum chromatographic result.