Paradoxically, an often-overlooked component of flash chromatography is the very first step! Loading your complex solution/mixture onto the physical column is not quite as simple as it may seem. Many students learn the basics of chromatography, and the theory behind separation and elution, yet the practical aspect of performing it is often left out of the classroom. While separation may be achieved by simply adding your mixture to the column, poor resolution, sensitivity, and selectivity may be observed. The key to loading a flash column is to understand how much can be loaded and whether to “wet” or “dry” load your column.

When performing chromatography, scale is always an important factor to consider. If you are separating single digit milligram amounts, overloading a column is likely not an issue you will run into. Indeed, compound detection or unexplained sample loss may be your biggest foe. Many chromatographers can attest to samples simply disappearing once injected on a flash column when dealing with small amounts. On the other end of the spectrum, large amounts of samples, especially complex mixtures, may prove difficult to separate at the scale they are made. To first determine how to properly load your flash column, you must find the column loading capacity.

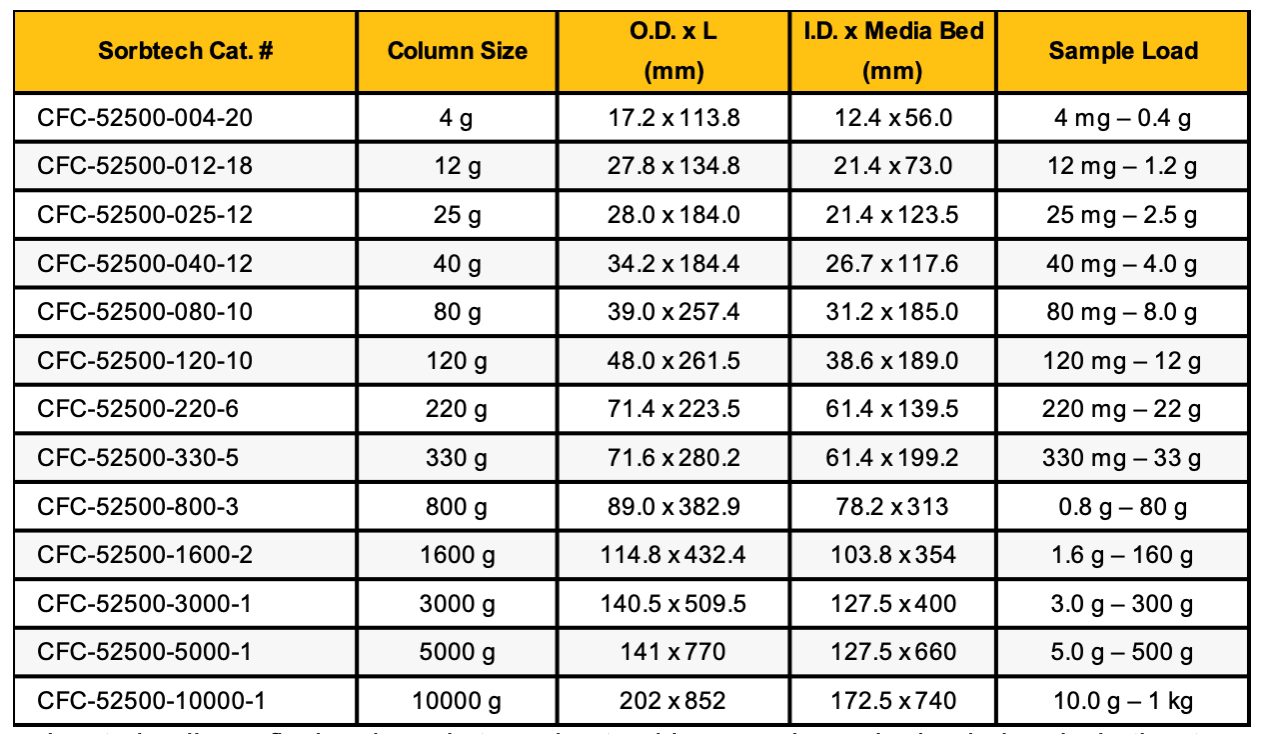

Often, manufacturers will advertise this on their columns, but many factors can affect the true loading capacity. For silica-based columns used in normal phase chromatography, the loading capacity tends to be maxed out at 10% of the media weight. Some sources will claim this is higher, up to 20% of the media weight on spherical media, and while there are situations where this is possible (such as low impurity amounts or highly separated components), a 10% max load is a better rule of thumb.

Following is a sample load table that we recommend to our users as a general application guide. Your purity requirements, sample homogeneity, sample dilution etc. should also be considered in determining the actual sample load.

Reversed-phase hydrocarbon-bound flash columns tend to have significantly lower loading capacity, often maxing out at 1-5% of the media weight. It is important to note that these are weight maximums, and preferably you should stay below these thresholds.

Along with maximums, minimums are an important consideration when loading flash columns. Injecting 5mg of material onto a 300g column will most certainly cause you a headache in trying to recover your sample. Often, manufacturers will also include a recommended sample minimum, which should be used as the baseline.

In addition to sample weight, mixture complexity and concentration must be considered. There is a stark difference between a dilute 100mg solution and a neat 100mg liquid when injected onto a column. Taking into account the dilution (or lack thereof) can prevent headaches down the road when you are placing that order for new columns as yours were overloaded and no longer function properly. Additionally, the separability between components plays a large role in determining the proper flash column. Compounds with Rf values (measures of retention) far apart from each other may get away with utilizing a smaller column than mixtures with incredibly similar compounds within them. If your retention times differ by only seconds on an HPLC, increasing the column media weight and subsequent efficiency may be necessary to achieve preparative separation.

We highly recommend doing an initial TLC qualifying separation to determine your best operating conditions for your purification needs. TLC will provide necessary and important information in regard to Rf and CV to assist in developing successful methods.

Column loading falls into two categories, aptly named “wet” and “dry” loading. In essence, the difference between the two involves dissolving a compound in the starting mobile phase or not. Often seen as simpler, wet loading is the go-to preferred method for many analytical chemists when loading a flash column. A mixture of your compound(s) is dissolved in a minimal amount of either the isocratic/initial mobile phase (for gradient conditions) or a solvent weaker than your eluant and injected directly onto the flash column with a syringe.

Sample Load Calculator

Excel Macro

Use this macro to determine the appropriate sample load volume based on column dimensions and sorbent particle size.

You may have to authorize this macro in Microsoft Excel prior to use.

by Dr. Robert Kerr, Director of Research and Development, Sorbent Technologies, Inc.

To perform a wet load, a few key criteria must be met, and considerations considered. First, is your mixture readily soluble in the mobile phase/solvent? A minimal amount of solvent is desired to avoid premature elution, and difficult-to-dissolve mixtures may need an excessive amount of solvent to adequately wet load onto a column. Second, it is also incredibly important to not use a solvent stronger than your mobile phase in elution power, otherwise, your separation will not behave accordingly and likely will fail. Often, chemists will make the mistake of injecting the dissolved mixture onto the column and removing the syringe prematurely. Backpressure is often generated when injecting, and there must be no resistance before removing the syringe or the mixture will leak back out the top of the column.

Dry loading may seem daunting, but the process has been increasingly made easier throughout the years. In essence, the sample is adsorbed onto either a silica, Celite, or other solid phase and introduced to the column/system as a fine powder. While traditionally, the introduction of the powder occurred by removing the top of the column and introducing the powder directly to the solid phase, dedicated solid loaders can instead be used. These tubes allow for solid phases to be added to the system without disturbing the actual column packing. The mobile phase then is run through the solid loader before reaching the column, functionally delivering the mixture in real time. This method is appropriate when your component mixture is not readily soluble in the initial mobile phase conditions or requires a later gradient to begin elution. It is crucially important to not use an excessive amount of silica/celite/solid phase when adsorbing your mixture, otherwise, band broadening or delayed separation may be observed. Add solid phase until a free-flowing powder is observed, often by adding solvent to make a slurry and then evaporating out the solvent.

With all this information, it may seem daunting to determine how best to load a column for a given synthesis/process. Often, chemists can use known mixtures with defined separations to determine whether a loading process/flash column size is appropriate for a given separation. Additionally, robustness and reproducibility can be confirmed via the injection of these known solutions after column runs. Column bleeding, improper separation, delayed or expedited elution, and more can be seen by tracking the performance of these known mixtures over time after multiple column injections. Proper cleaning techniques, column rinsing, and non-overloading can allow columns (primarily reversed phase) to be used over and over again with reproducible results. This often is not the case with preparatory silica columns, which often either get impurities “stuck” in them, become chemically entangled with “junk” for lack of a better word, and lose their separation power after use. At the end of the day, trial and error is often the best choice when determining column load principles, and pilot runs are recommended to confirm separations before large-scale chromatography.

About the Author – Ransom Jones

Analytical Scientist at Mikart LLC, focusing on product development for drug substances and drug products. MSc in Pharmaceutical and Biomedical Sciences from the University of Georgia. Background in nucleoside synthesis for antiviral purposes. Extensive knowledge in the drug development pipeline, including API synthesis, toxicology in-vitro testing, formulation development, FDA regulations (cGMP/21 CFR 210/211), pharmaceutical analysis, and more.

Graduate work focused on medicinal chemistry, specifically on antiviral nucleoside analogs. Included leading projects, complex synthetic organic chemistry, analytical development (NMR, HPLC, LC, Mass Spec), and more.

Experienced in solid dosage formulation development, including acetaminophen tablets and piroxicam capsules. Hands-on experience with rotary tablet press, dissolution, TGA/DSC, disintegration, HPLC, spray dryer, and more.

Download

Download